Chiller set up and products are vital parts in many various companies and industries. They are to blame for trying to keep structures and rooms cooled, holding tools great, and so are even integrated straight into sure procedures or procedures. In the following paragraphs, we are going to examine just what exactly this industrial refrigeration gear does, what forms you may have to pick from, and what they are used for.

What on earth is It?

Chiller set up consists of the process of installing different pumps, condensers, piping, together with other parts to make a cooling program. This industrial refrigeration gear employs either drinking water vapor or absorption to drag the heat away from a liquid for example lithium bromide Answer, glycol, inhibitors, drinking water, or Another fluid. To cool this liquid, these units use air, water, or evaporation.

Chiller Installation -- Types Of Programs

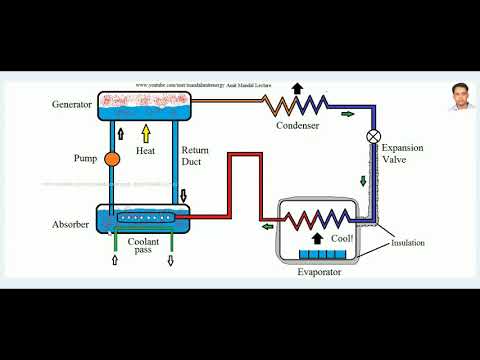

Absorption chiller set up will involve equipment with 6 major sections -- an answer pump, generator, warmth exchanger, condenser, evaporator, and an absorber. Liquid is pumped to the warmth exchanger where it's heated. From there, it flows past tubes full of very hot drinking water or steam in which it truly is heated into the boiling point, releasing steam in the condenser higher than. The lithium bromide from the solution goes back brand in the ammonia refrigeration contractors industry to the heat exchanger. The steam is cooled within the condenser, as well as the humidity collects at the bottom. At this time, the lithium bromide goes to your evaporator plus the absorber where it heads back to the answer pump to accomplish the cooling cycle.

With vapor-compression industrial refrigeration devices, the liquid is set stressed and boiled in a very boiler until eventually it will become dry, saturated vapor. Then, goes via a turbine wherever it cools and loses its pressure. From there, it is sent to some condenser where by it results in being a saturated and cooled. These programs use 5 varieties of compressors powered by fuel, electrical, or steam turbines -- centrifugal, reciprocating, screw-pushed, or scroll compressors.

Industrial Chiller Refrigeration Devices

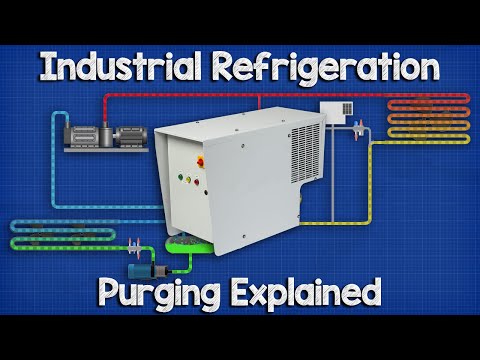

These can be found in two principal designs. A closed loop system pumps a fluid combined with condition additives, which are held at a particular stress and temperature, between the process plus the Software within a ongoing cycle. Along the way in which, the fluid travels as a result of pumps, valves, in addition to a condenser. Open loop industrial refrigeration equipment pumps the liquid from a significant tank in the technique and again for the tank so as to preserve items cool. These devices normally use water, but they also can use air to chill.

Industrial refrigeration products is available in a variety of kinds and employs, but in spite of how they compare technically, they are still important to the Procedure of many business and industrial businesses. What this means is you need to be sure chiller installation is completed appropriately and that these programs are in leading working order continually. Recognizing the basics will allow you to look for a service provider that will help you do just that.

ALTA Refrigeration

403 Dividend Drive

Peachtree City, GA 30269

(678) 554-1100